Optimized Design & Testing Evaluation

Since our founding, leveraging in-house design expertise, we have successfully carried out research and development tasks for high-precision gears, high-speed gearboxes, and defense industry products. We continue to engage in the development and mass production of civil business sectors, such as high-speed turbo gears, ball screws, and roller screws.

With the developmental experience gained, we possess comprehensive R&D capabilities and engineering prowess, from numerical analysis of gear Trains and bearing life prediction to performance and environmental testing of individual components and assemblies.

·Component and System Design

·Optimization for size compactness

·Shape optimization considering interface

·3D modeling and interface verification

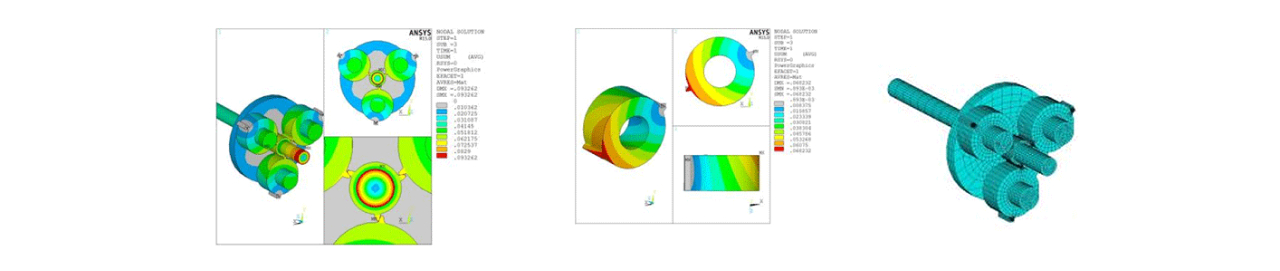

·Structural analysis, vibration analysis, and flow analysis

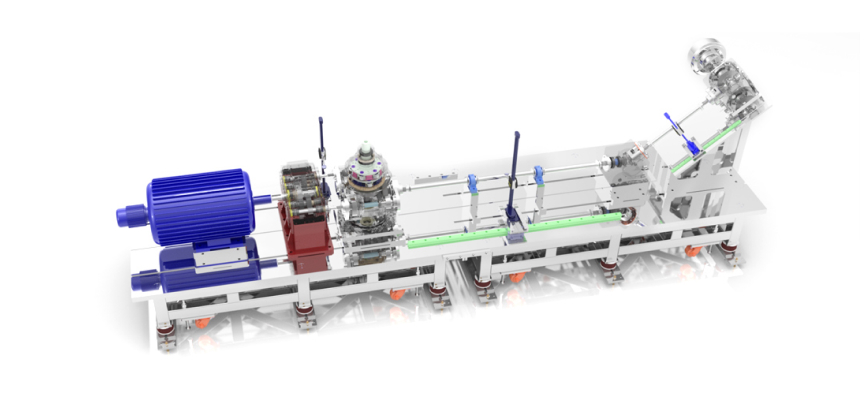

·Ultra-Precision Machining/Assembly Technology

·Possession of high-precision machining tools & process design

·Heat treatment and surface treatment

·Component (individual part) performance testing

·Assembly Performance Testing

: Self-conducted no-load/load testing, temperature testing

·Environmental Testing(MIL-STD Standards) : External certified institutions

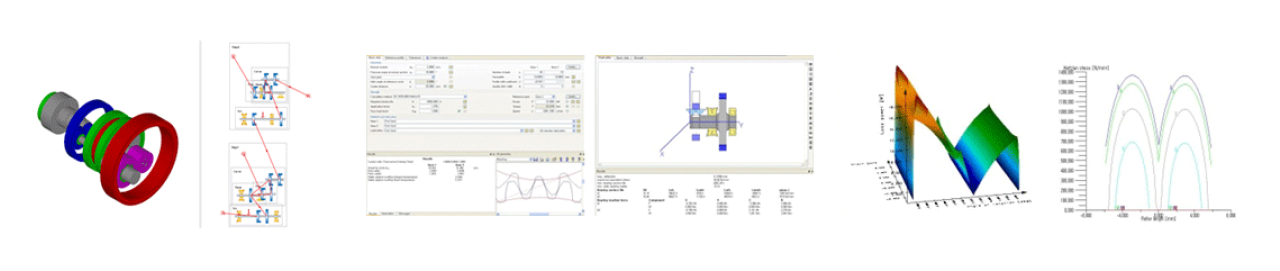

Modeling and gear strength analysis

Gear train gear strength analysis and bearing characteristic analysis

Simulation

Structural analysis through finite element geometry, deformation, load analysis

Core Technology

Gear design according to operational conditions

Optimized design technology through gear ratio requirements, drive power-based gear Train design, and lifespan calculation

Bearing selection and lifespan prediction according to load, rotational speed, and load conditions

Lubrication design according to operational conditions

Selection of cooling methods considering heat generation

Lubrication method selection according to operational conditions (immersion, spray, etc.)

Design of lubrication systems including flow rate, nozzle diameter, etc., based on the lubrication method